5 Things You Might Not Know About the Durability of Rubber Keypads

Understanding the Various Sorts Of Rubber Keypads and Their Crucial Utilizes in Everyday Innovation

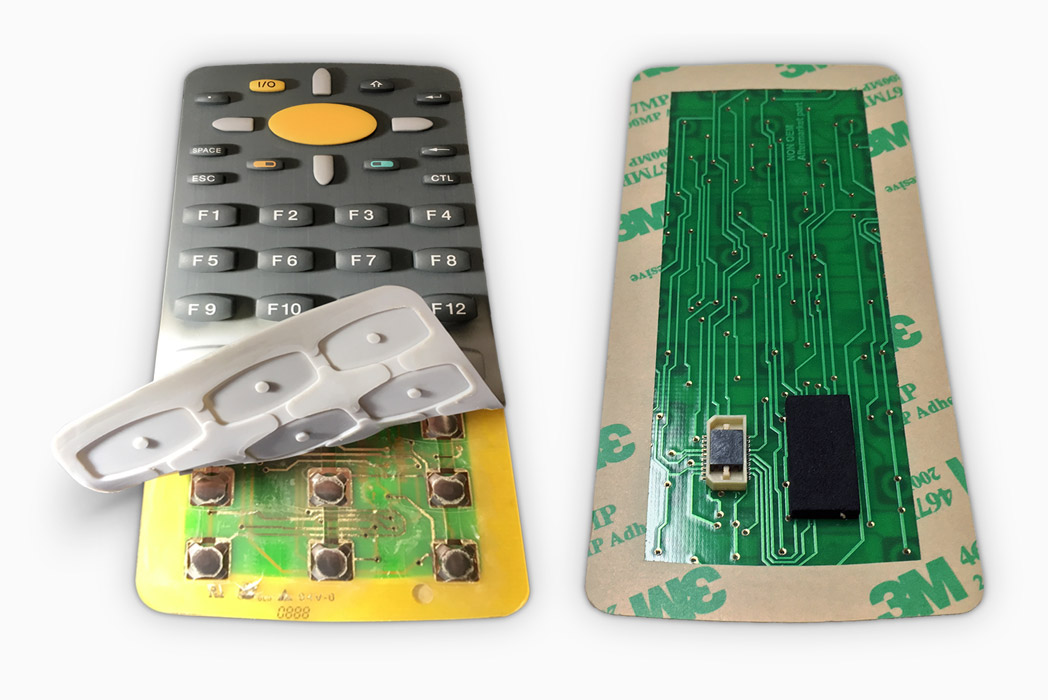

Rubber keypads play an essential role in modern-day technology, serving as interfaces for various tools. Different types, such as silicone rubber and membrane keypads, deal with particular applications and user demands. Each type offers special benefits, from flexibility to space-saving layouts. Understanding these differences is essential for choosing the best keypad for an offered application. This exploration will certainly reveal not just the types readily available however additionally their impact across numerous industries.

Review of Rubber Keypads

Rubber keypads are functional input gadgets widely used in various electronic applications. Their construction normally involves silicone or rubber materials, which give a special responsive action when pressed. This tactile feedback boosts customer experience by permitting people to determine crucial activation without requiring to consider the gadget. Rubber keypads are usually used in customer electronic devices, clinical tools, and commercial tools, using durability and resistance to environmental elements such as moisture and dirt. In addition, they can be personalized relating to shade, dimension, and form to fulfill particular layout demands. The adaptability of rubber keypads permits for unification right into complicated designs, making them ideal for small devices where space is a restraint. Their cost-effectiveness and simplicity of manufacturing add to their widespread fostering across different industries. Overall, rubber keypads play a crucial function in boosting functionality and capability in plenty of technical applications.

Sorts Of Rubber Keypads

Numerous types of rubber keypads accommodate different applications and customer preferences. Amongst the most common types are silicone rubber keypads, recognized for their versatility and toughness, making them ideal for portable devices and clinical equipment. An additional type consists of conductive rubber keypads, which feature ingrained conductive products enabling effective electric contact, usually discovered in digital gizmos. Membrane keypads, a subcategory of rubber keypads, include layers that develop a level user interface, commonly used in appliances and industrial applications for their space-saving design. In addition, custom rubber keypads can be tailored to specific designs or functionalities, appealing to particular niche markets such as gaming or specialized equipment. Each kind serves distinct functions, enhancing user interaction and tool integrity across various industries. These variants ensure that rubber keypads satisfy the diverse requirements of consumers, offering performance and convenience in day-to-day modern technology.

Key Features of Rubber Keypads

Rubber keypads are recognized for their vital functions that enhance use and performance. Their toughness and long life make them excellent for numerous applications, while tactile feedback qualities assure customer complete satisfaction. Furthermore, the personalization choices available permit customized styles to meet details requirements.

Sturdiness and Longevity

Tactile Response Characteristics

Keypads made with rubber materials use noteworthy responsive action attributes that boost individual communication. These keypads give a distinctive responses device, permitting customers to feel a visible click or resistance when tricks are pressed. This tactile comments is crucial in applications where accuracy and precision are paramount, such as in clinical devices or commercial devices. The soft qualities of rubber contributes to a comfy pressing experience, decreasing finger fatigue throughout extended use. Additionally, the design usually enables for differing essential heights and forms, additionally boosting the tactile experience. This responsiveness not just aids in protecting against unexpected presses yet also boosts total individual complete satisfaction, making rubber keypads a preferred selection in countless technological devices.

Modification Options Available

Benefits of Utilizing Rubber Keypads

Rubber keypads offer countless advantages that make them a preferred option across different applications. One vital benefit is their resilience, as they can hold up against comprehensive damage, making them appropriate for high-usage atmospheres. Additionally, rubber keypads supply excellent resistance to water, dirt, and chemicals, improving their durability and reliability. The soft-touch surface area guarantees customer comfort, lowering finger fatigue throughout extended usage.

Additionally, their tactile comments boosts user experience, enabling for specific input recognition. The adaptability in layout also permits personalized shapes and colors, allowing smooth assimilation right into numerous items. Rubber keypads are commonly cost-efficient compared to other materials, making them an affordable alternative for manufacturers. Rubber Keypads. They likewise support silent operation, which is perfect for atmospheres where noise reduction is crucial. On the whole, the mix of personalization, sturdiness, and comfort makes rubber keypads a useful element in numerous technological tools

Typical Applications in Consumer Electronic Devices

Rubber keypads are extensively used in different consumer electronic devices, serving essential functions in enhancing user communication. They are generally found in push-button control user interfaces, clinical tool keypads, and home appliance controls. These applications highlight the adaptability and functionality of rubber keypads in everyday innovation.

Remote Control Interfaces

Remote control interfaces are fundamental components in modern consumer electronics, enabling individuals to engage effortlessly with gadgets from a distance. These user interfaces make use of rubber keypads to supply tactile comments, improving customer experience. Common applications consist of tv remotes, video gaming controllers, and smart home gadgets, where ease of use is vital. The layout of rubber keypads enables for resistance, toughness, and versatility to use, making them optimal for frequent use. Different configurations, including multi-button and single-button formats, satisfy diverse user demands and preferences. Furthermore, the water-proof and dustproof buildings of rubber keypads guarantee dependable performance in numerous settings. Generally, rubber keypads in remote user interfaces play a crucial role in simplifying interactions with technology, promoting convenience and access for customers.

Clinical Device Keypads

Keypads in clinical gadgets offer a necessary function, Visit Your URL making it possible for medical care specialists to run devices effectively and precisely. These rubber keypads are frequently located in devices such as high blood pressure monitors, glucose meters, and analysis devices. Their tactile responses guarantees that individuals can input commands without obscurity, which is vital in high-stakes settings. Additionally, the sturdiness and resistance to moisture and chemicals make rubber keypads excellent for constant usage in scientific setups. The ergonomic style commonly accommodates gloved hands, enhancing use. Personalized layouts allow makers to tailor keypads to details gadget features, simplifying procedures. Overall, medical gadget keypads play a substantial duty in improving patient treatment via reliable and user-friendly interfaces.

Home Appliance Controls

Home device controls play a crucial duty in the functionality and individual experience of day-to-day consumer electronics. Rubber keypads supply responsive feedback and longevity, making them excellent for tools such as microwaves, washing devices, and coffee machine. These keypads give intuitive interfaces, enabling individuals to conveniently browse setups navigate to this site and programs. The soft-touch design reduces the danger of unexpected activation while making certain a comfy experience. In addition, rubber keypads are immune to moisture and dirt, which is crucial in cooking area and washing environments. They can also be personalized for particular features, improving usability. Overall, rubber keypads contribute considerably to the performance and integrity of home devices, making sure that consumers can operate their gadgets easily and efficiently.

Industrial and Medical Use Rubber Keypads

Rubber keypads have actually come to be basic parts in different industrial and medical applications due to their toughness and integrity. In commercial setups, these keypads are commonly made use of in machinery controls, offering a responsive user interface that withstands extreme settings, consisting of direct exposure to chemicals and extreme temperatures. Their resistance to tear and put on makes them excellent for heavy-use circumstances, where consistent efficiency is important.

In the clinical field, rubber keypads offer crucial functions in gadgets such as analysis equipment, client monitoring systems, and research laboratory tools. Their simplicity of cleaning and capacity to resist contamination help in preserving health standards considerable to medical care setups. In addition, the customizability of rubber keypads permits ergonomic designs customized to individual needs, improving access for both doctor and people. In general, the convenience of rubber keypads assurances their proceeded relevance in commercial and medical technologies.

Aspects to Consider When Deciding On Rubber Keypads

When picking rubber keypads, a number of crucial variables need to be thought about to assure peak performance and compatibility with certain applications. The desired usage plays a significant role; various environments, such as industrial or clinical settings, might need unique features like antimicrobial homes or boosted resilience. Second, the responsive feedback is essential for user fulfillment; a keypad ought to offer a comfortable and responsive experience.

Furthermore, the style and format should be thought about, as custom-made forms and dimensions might be required for details tools. The material make-up influences both the keypad's longevity and its resistance to chemicals or severe temperatures. Furthermore, compatibility with electronic elements is vital; ensuring that the keypad incorporates perfectly with existing modern technology avoids operational problems. Lastly, cost-effectiveness must be examined, balancing top quality and spending plan constraints to attain excellent worth without compromising efficiency.

Often Asked Questions

Can Rubber Keypads Be Custom-made for Particular Designs or Logos?

Rubber keypads can certainly be tailored for his response particular styles or logos. Suppliers offer various choices, enabling customers to inscribe distinct graphics or text, improving branding while keeping capability in varied applications across numerous industries.

Just How Do Rubber Keypads Contrast to Membrane Switches?

Rubber keypads provide responsive feedback and resilience, while membrane layer buttons offer a more streamlined layout and are typically thinner. Each has distinct benefits, making the option dependent on specific application needs and user preferences.

What Upkeep Is Needed for Rubber Keypads?

Rubber keypads require normal cleaning to avoid dust buildup, occasional examination for wear or damages, and proper storage away from extreme temperatures. Guaranteeing they are devoid of wetness improves their longevity and capability.

Exist Environmental Interest In Rubber Keypad Production?

Yes, environmental issues develop from rubber keypad manufacturing, consisting of making use of non-renewable sources, pollution throughout making procedures, and obstacles in reusing. These variables add to an expanding awareness of sustainability in the electronics industry.

For How Long Do Rubber Keypads Generally Last?

Rubber keypads usually last between 5 to ten years, relying on usage and ecological conditions. Elements such as direct exposure to warm, sunlight, and chemicals can significantly affect their toughness and total life expectancy.

Different kinds, such as silicone rubber and membrane layer keypads, cater to particular applications and user needs. Membrane layer keypads, a subcategory of rubber keypads, consist of layers that develop a level interface, commonly utilized in devices and commercial applications for their space-saving design. Several materials are used in keypad production, rubber keypads stand out due to their remarkable longevity and durability. Keypads made with rubber materials supply significant responsive reaction features that enhance individual communication. In addition, the customizability of rubber keypads permits for ergonomic styles tailored to user needs, boosting ease of access for both clinical specialists and individuals.